I. Introduction: Why Field Technicians Still Struggle

Despite the proliferation of connected HVAC systems and smart devices, field technicians still face a frustrating reality: on-site troubleshooting is slow, reactive, and heavily dependent on tribal knowledge or Tier-2 support. While cloud platforms have enabled centralized monitoring, these benefits rarely extend to third-party contractors handling real-world installations and repairs.

Contractors, who are often not deep product experts, must decipher cryptic device logs or wait on phone support to interpret fault codes. This results in extended downtime, repeated visits, and rising costs — all of which chip away at customer satisfaction and operational efficiency.

That’s where intelligent, AI-augmented field apps can make a significant impact — by transforming raw telemetry into actionable insights and delivering them directly into the hands of the technician. But doing this right requires thoughtful architecture, practical UX, and tight

II. The Ground Reality We Addressed

We worked with an HVAC and connected appliance OEM that was receiving thousands of telemetry pings and error logs daily from its installed base. The devices — deployed in homes, offices, and commercial properties — would push logs to the cloud whenever a fault was detected.

However, contractors called in to service these devices faced three recurring challenges:

- Inconsistent log formats: Some devices sent verbose stack traces; others offered only terse fault codes.

- No severity context: Contractors couldn’t tell whether a given error was critical, intermittent, or benign.

- Reliance on central support: Most resolution required a phone call to Tier-2 support to interpret issues, slowing down the service process.

The OEM needed a contractor-facing app that could bridge this gap — enabling field techs to diagnose issues quickly, reduce dependency on centralized teams, and improve first-time fix rates. The goal was to create a self-service field companion, powered by AI, resilient in offline conditions, and secure by design.

III. Architecture Overview: Offline-Resilient, AI-Integrated

To support a globally distributed and mobile contractor workforce, we designed a lightweight but robust mobile app architecture with the following key elements:

- Cross-platform mobile app using React Native (Flutter as fallback for future regions)

- Offline-first architecture using local SQLite/Realm DB to cache:

- Recent telemetry data (last 24 hours)

- Last 3 error events

- Device metadata (model, firmware version, install date)

- QR/Barcode scanner to retrieve MAC ID or serial number → triggers cloud lookup

- Cloud API integration to fetch historical fault logs and send current telemetry

- Edge caching and background sync to ensure real-time performance, even with poor connectivity

This ensured that technicians could still work with the latest known data — even in basements or remote buildings with limited signal — and sync seamlessly once they were back online.

IV. AI-Powered Fault Signature Detection — How It Works

At the heart of the solution was an AI model trained on historical device faults. We engineered the fault detection flow as follows:

- Data Preprocessing:

- We ingested 3 years of historical fault logs from over 100,000 devices.

- Each log was tokenized into sequences capturing timestamps, error codes, operating conditions (temperature, pressure, humidity, etc.)

- Model Training:

- We used XGBoost for structured error code patterns and CNN/LSTM models for time-series telemetry.

- Training occurred in AWS using SageMaker, with Azure ML used for benchmarking.

- Real-Time Inference:

- When the app detects a fault, it constructs a signature (last 24h telemetry + current log) and sends it to the inference endpoint.

- The model returns:

- Predicted fault classification (e.g., “Compressor Failure”, “Low Refrigerant”, “Sensor Drift”)

- Confidence score

- Recommended next steps from the OEM’s support knowledge base (KB)

- Feedback Loop:

- Contractors mark whether the resolution worked.

- This outcome data is logged and periodically used to retrain the model, improving accuracy over time.

This created a living AI system — one that continuously learned from the field, improved its predictions, and adapted to emerging patterns.

V. Field UX Designed for Speed

Field tools must prioritize clarity and speed — especially under time pressure. Our UX design focused on reducing cognitive load and maximizing usability:

- Quick Scan Experience: Scanning the device’s QR code brings up all known metadata and error history instantly.

- Pre-Filled Summaries: The app auto-fills device health summaries using cloud data, saving techs from manual inputs.

- Visual Fault Indicators: Color-coded alerts (green/yellow/red) help prioritize severity at a glance.

- Offline-First Mode: Techs can capture observations and attempt fixes offline; data syncs automatically once reconnected.

- Multi-Language Support: App supports 6 languages to aid international deployments.

Every interaction was benchmarked against time-to-resolution, ensuring the app helped — not hindered — the field workflow.

VI. Business Impact Delivered

Within 3 months of regional deployment, the results spoke for themselves:

- 30% reduction in support ticket volume due to fewer contractor escalations

- First-time fix rate jumped from 62% to 86%, improving service margins

- 25% decrease in average visit time, allowing techs to handle more jobs per day

- 60% fewer Tier-2 support escalations, reducing central team workload

Beyond efficiency, the app also improved contractor satisfaction and brand loyalty. Field techs felt more empowered, and customers experienced faster resolution — a clear win for all stakeholders.

VII. Security, Access & Permissions

Given the app was exposed to external contractors, strict security controls were non-negotiable:

- Authentication via AWS Cognito (regions using Azure B2C integrated similarly)

- Role-based access: Contractors could only access devices assigned to their account or job ticket

- Token-based API access: Device metadata, logs, and inference endpoints required scoped tokens with expiration

- Audit Trails: Every action was logged — from scan to resolution feedback — supporting compliance and service analytics

These measures ensured that operational transparency didn’t come at the cost of data privacy or misuse.

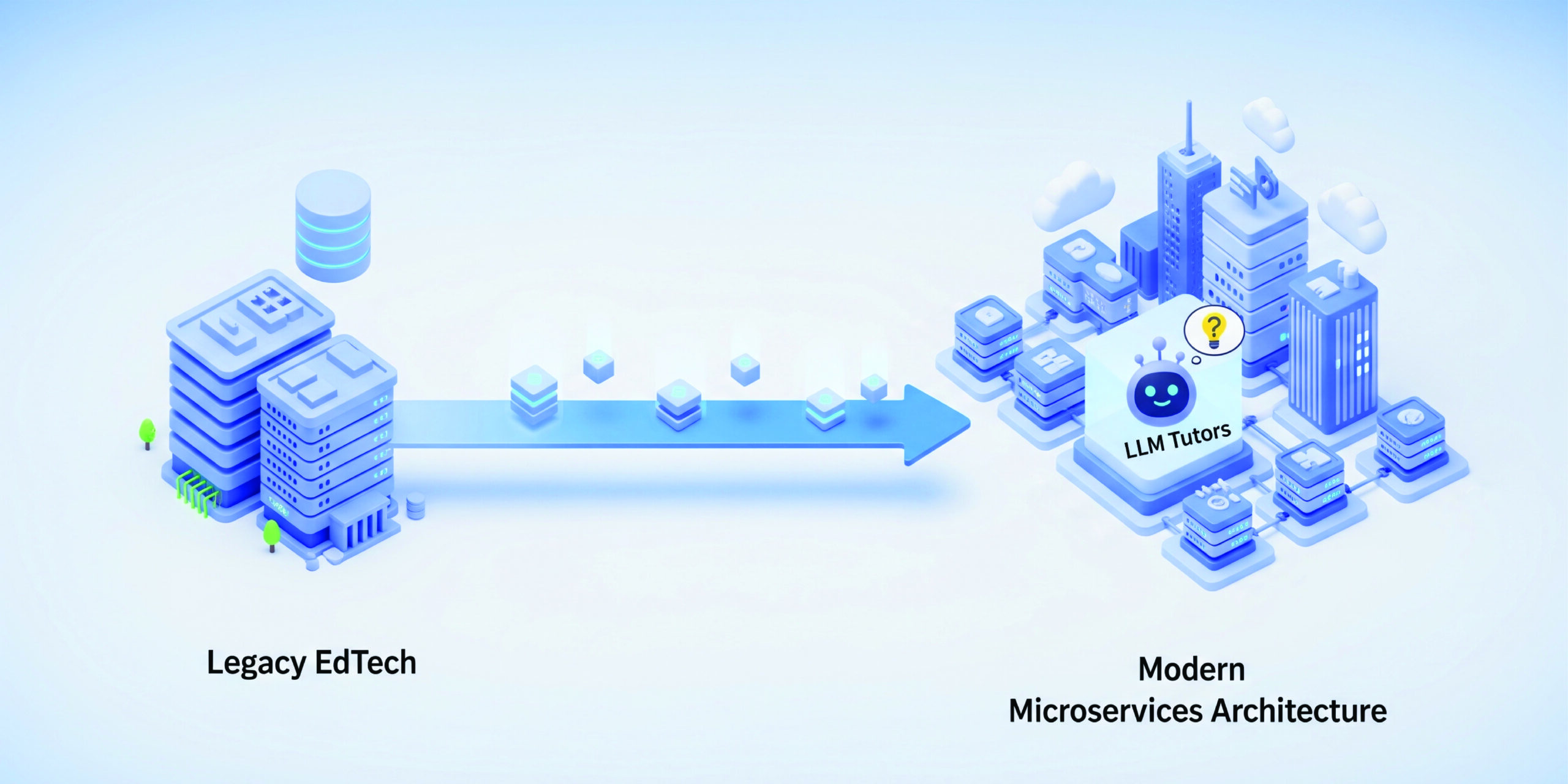

VIII. Future Enhancements in Pipeline

With the app’s core working well, we’re now exploring features to further expand its value:

- Image-Based Diagnostics: Upload device photos → run computer vision models to detect physical faults (e.g., burned capacitor, pipe leakage)

- Inventory Integration: Suggest spare parts based on detected faults, auto-check local availability

- LLM-Powered Support Chatbot: Integrate with Azure OpenAI / Amazon Bedrock to answer contractor queries using the full support KB

These enhancements aim to shift the tool from being reactive → to predictive → to prescriptive — creating an intelligent assistant for field troubleshooting.

IX. Key Takeaways for Smart Product OEMs

- AI isn’t just for dashboards — when deployed at the edge, it becomes a force multiplier for real-world support and service.

- Contractor-facing apps are an overlooked opportunity to improve service ops, build brand trust, and reduce cost.

- Offline-first, secure, and AI-integrated architectures are key to success — especially in HVAC, Consumer Electronics, and Smart Devices.

- Every feedback loop matters — with every fix marked and learned from, the system gets smarter and your support costs go down.

For OEMs looking to scale field service without scaling headcount, this kind of solution represents not just a cost optimization — but a customer experience breakthrough.